RepMat

Replicating Materials Library

Democratize materials and technological knowledge.

Welcome to the Virtual library of RepMat!

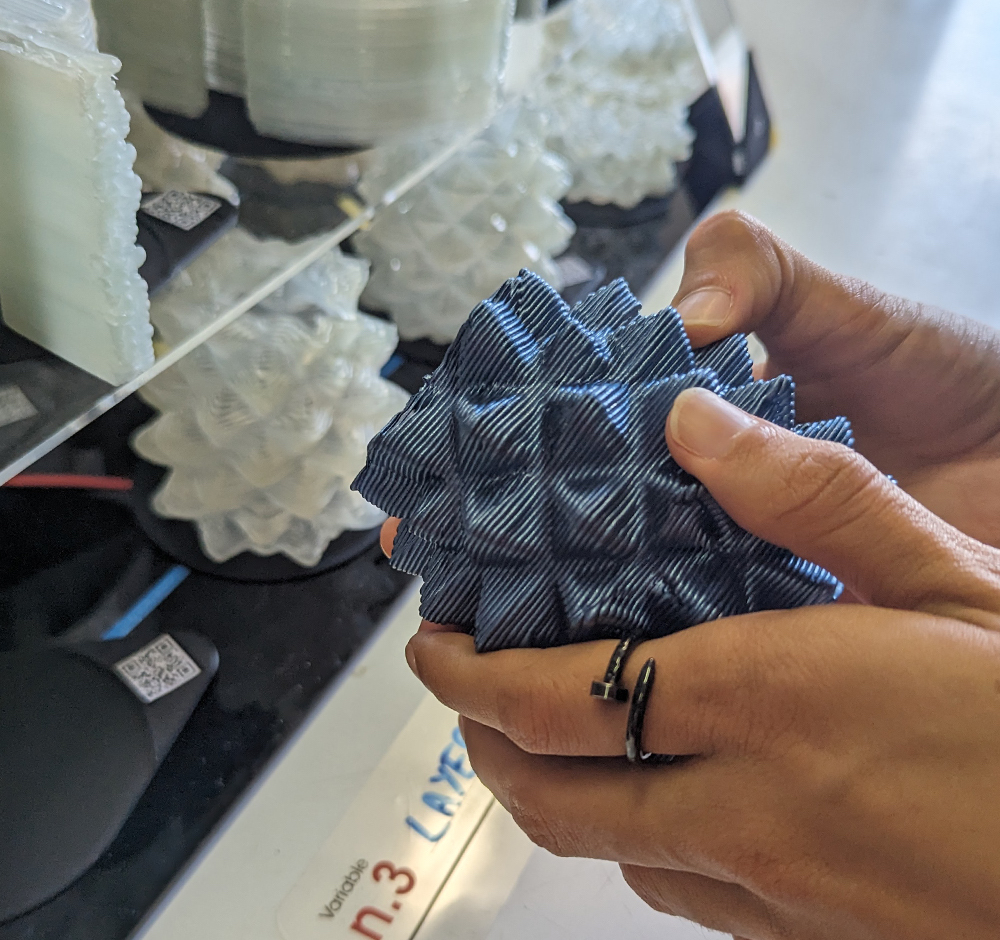

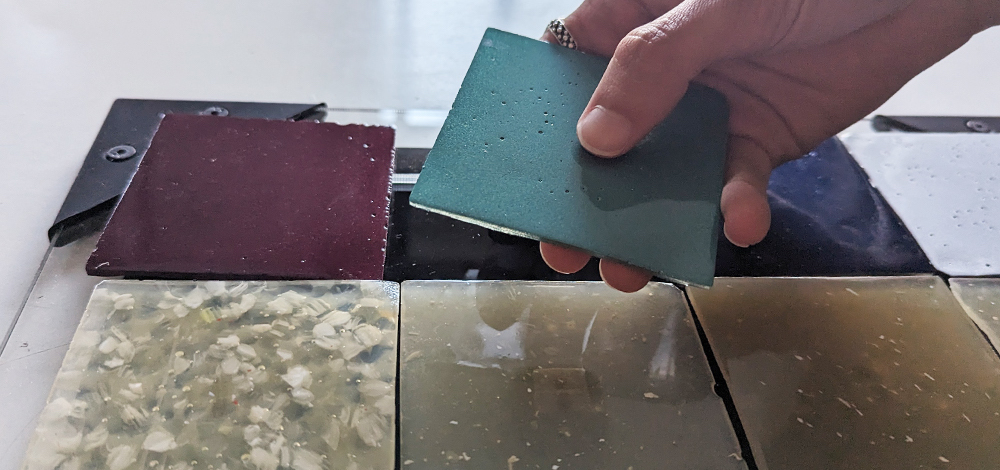

RepMat Library, REPlicating MATerials Library, is an Open Source Materials Library designed to share circular sustainable practices linked to new materials and technologies, in particular 3D printing.

This library contains useful data and information regarding materials, products, and 3D printing processes connected to circular economy and sustainable development practices. It has been designed to encourage the use and spread the knowledge and use of materials for new applications and products connected to circular economy principles, stimulating new work on them.

Do you want to know more about it? Check this link!

Start your visit from here

A collaborative, distributed, and open source materials library

RepMat is meant as a collaborative distributed materials library, following the principles of open source and open design. It can be freely replicated within collaborative spaces, such as makerspaces, and the library itself can grow thanks to the contribution of different users and communities.

Do you want to contribute with your samples? Check this link!

Press Release

Last publication

Last event/media source

entitled "Circularity by design, materials and additive manufacturing: fostering sustainable and circular materialities

enabled by additive manufacturing" and supervised by prof. Marinella Levi and prof. Valentina Rognoli.

The RepMat Library is an Open Source Hardware Educational Tool certified by OSHWA (Open Source Hardware Association) and released under the CERN-OHL-S-2.0 (hardware and documentation) and GNU General Public License (GPL) 3.0. (software).

Certification number: [OSHW] IT000018 | Certified open source hardware | oshwa.org/cert